Equipment: TSI 101

Snubbing Operations. • P & A • Work over • Through tubing • Fishing • Milling • On land or Off shore

TSI-101 Hydraulic Workover Unit

Key Advantages

- Compact footprint

- Reduced loads

- Efficient trip times

- ESG awareness integration

- Competent crewing and leadershisp

- Robust management system

- Advanced performance monitoring

TSI-101

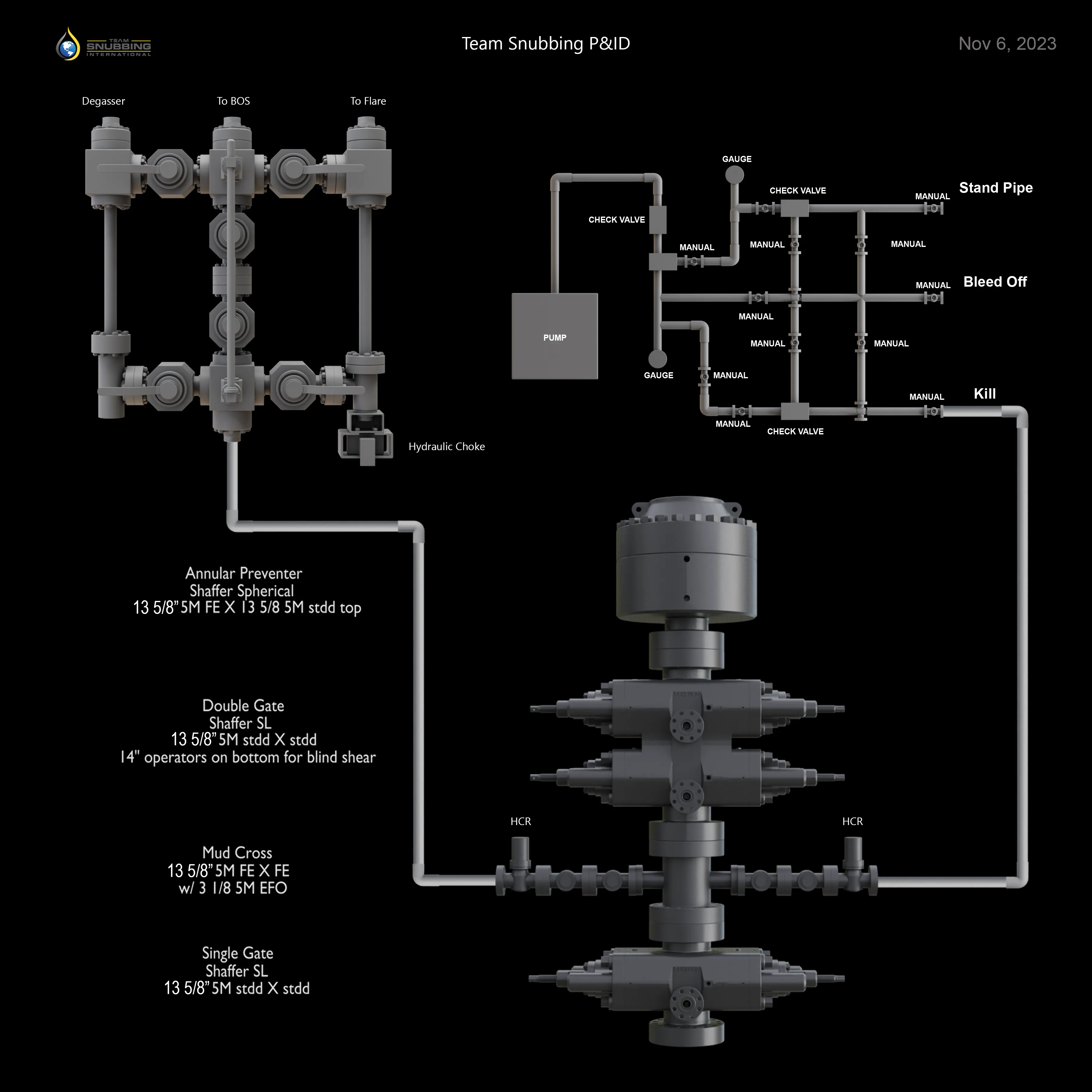

Pressure Tests, Kill & Bleed Off Systems

- Test pump & fluid for testing

- Pump, bleed off tank & lines

- Complete certified iron packages inclusive of coflex hoses

- Kill pump and fluid management options

Well Control

- 6 station closing unit with backup and remote panels located in work basket

- Snubbing packages available

- Extensive secondary (snubbing) accumulator system integral

- Extensive primary bop system and accumulator support packages

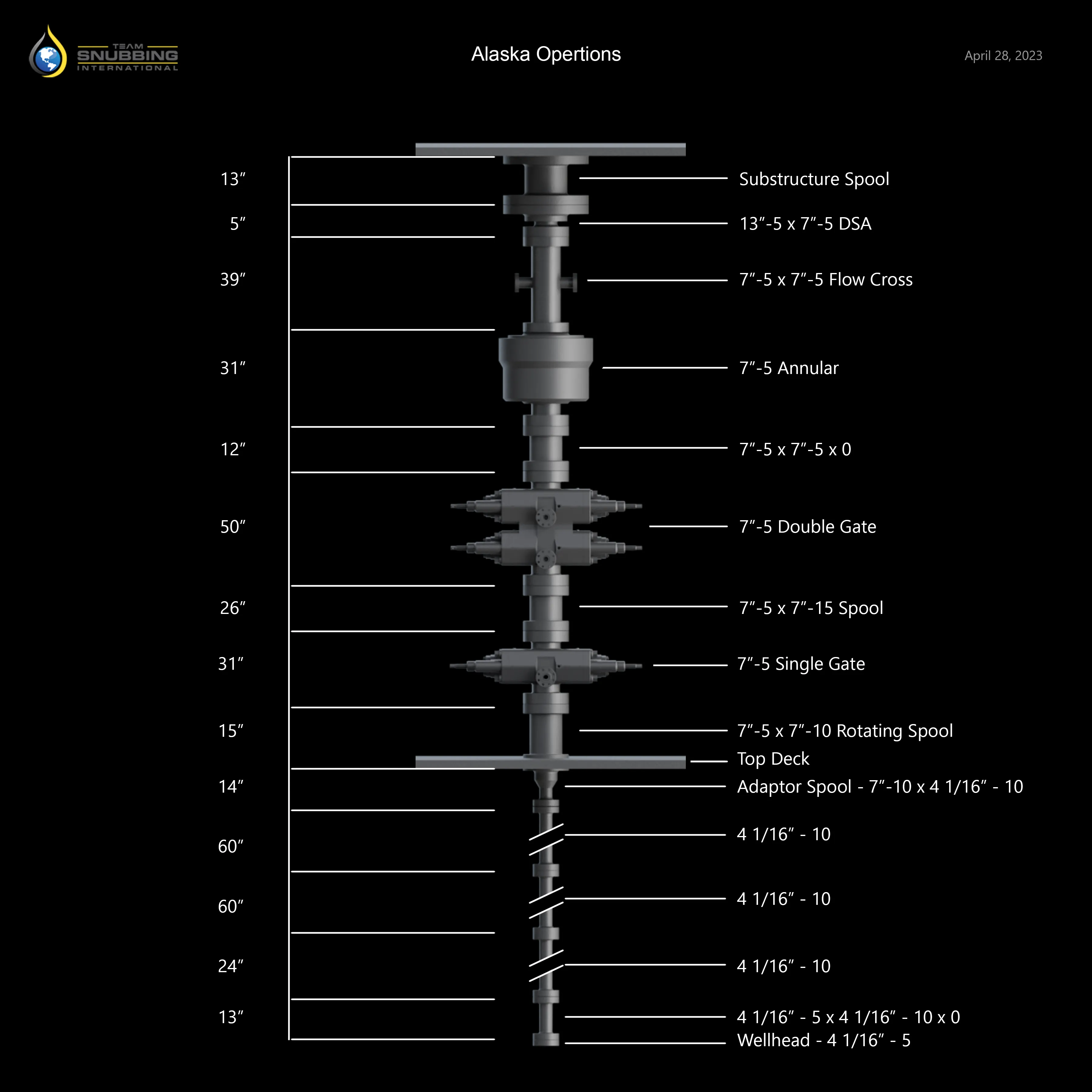

- 7-1/16” to 13 5/8” stack designs

- Shear ram included in all stack designs for 7 1/16” and 13 5/8” bops

Equipment Highlights

- 340K Hydraulic Workover Unit/Snubbing Unit:

- 12’ stroke

- 7-1/16” or 13-5/8” configurations available

- Heavy duty capacity gin pole with counter balance winches

- Quinta plex 1000HP Skid-Mounted Pump:

- 3″ x 6″ stroke

- 15,000 psi WP

- 13 5/8” x 10′ work window

- Serva SPM 600:

- 3” x 6” stroke

- 15,000 psi WP

- 460,000 lb rated substructure with stair towers

-

Trailer mounted doghouse & generator

- Self contained fluid management system